Biologically Treat Manure

Are You Paying Attention to the Livestock in Your Manure Pit? Why Biologically Treating Manure Matters.

Mention the word “livestock,” and images of hogs, beef or dairy cattle probably come to mind. But if you have a manure pit on your farm, you’ve got valuable resources in there, too. They’re just so tiny you can’t see them.

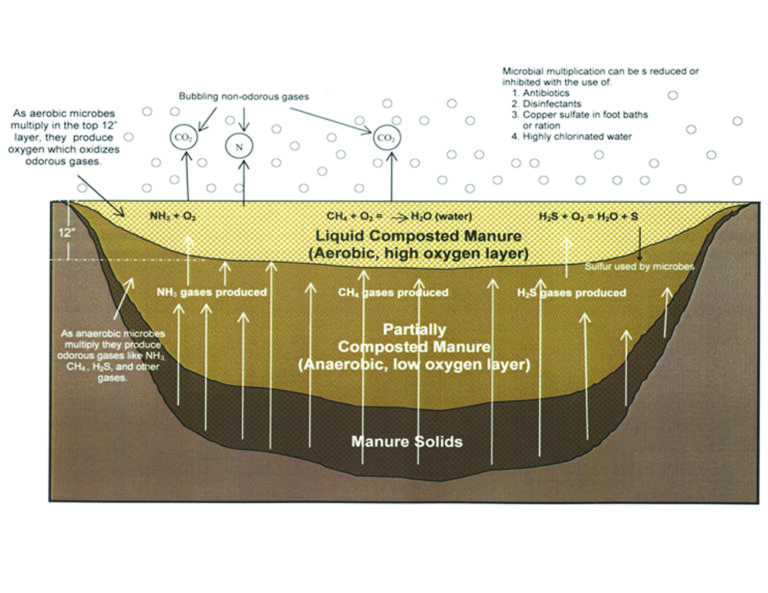

Your pit is filled with billions of microbes. While they’re out of sight, they shouldn’t be out of mind. Understanding the proper care and feeding of desirable microorganisms can reduce odor issues, flies and other nuisance problems, while providing a more desirable end product to fertilize crops.

Before we delve into the why and how of biological manure treatment, let’s start with the big picture first. In a sense, agriculture is all about managing energy flow. This energy flow begins when growing crops capture solar energy to grow and produce grain. When farm animals eat this feed, the energy in the grain builds body mass and helps produce meat, milk or eggs.

Along the way, some of this energy is excreted in the animals’ manure. This excreted energy becomes a food source for microorganisms that live in the manure. Once the microorganisms deplete the available energy, the manure can no longer support microbial activity. At this point, the manure will not decompose further and is considered biologically stable.

When these natural systems work properly and biological systems are in balance, manure is quite easy to manage. When things get out of balance, however, you can experience a variety of challenges. Some of the issues in today’s livestock industry can impact you operation financially. These issues can be managed with know-how and application processes in working with experienced consultants and trusting companies. The following issues are concerns and situations producers are facing today and there are solutions to mitigate:

- Crusting and bottom sludge. When crusts form in a manure pit, they often look like floating tabletops. Even if you try to break them up, they typically form again. Sludge can also form on the bottom of the pit. This sludge tends to stick around, even when the pit is pumped out. Not only does this reduce the storage capacity of your pit, but prevents valuable nutrients from reaching the field.

- Troublesome flies. Flies are a part of any livestock farm and can quickly get out of control. “Flies have a lifespan of 28 to 30 days,” said Chris Chodur, manure and livestock specialist with ProfitProAG. “On average, flies have an opportunity every two weeks to multiply.” Flies go down into manure pits to lay their eggs. Pits offer a perfect place for this, since they provide a moist, nutrient-rich environment filled with organic matter. “We see a lot more fly challenges where pits have crusts and a lot of solid matter,” Chodur said.

A rampant fly problem can:

- Damage livestock carcasses. When flies bite hogs, it’s irritating and painful for the animals, plus it can cause swelling. Damaged carcasses cost you money. “If the packing plant docks you $14 to $15 per hundredweight, this can cost you $40 to $50 per pig,” said Chodur, a former hog buyer.

- Spread disease. Flies traveling from pit to barn can transmit harmful viruses and pathogens that can make animals sick and affect production which can cost you financially.

- Foaming. We hear of a lot of foaming issues in the swine finishing industry today. Foam can also grow a couple feet a week and climb up the sidewalls and curtains of a livestock barn. While university researchers and scientists at various Ag organizations have tried to determine what causes foam, results have been elusive. While distillers dried grains in the feed appeared to be part of the issue, these studies haven’t provided all the answers. One thing is clear—foaming is a microbial process that occurs in specific conditions. “During the summer months, microbial communities in the manure pit are more active and re-populate,” Chodur said.

“That also means the majority of the organic matter in the manure is spent, because the microbes have digested it. Typically, when the pit is 80% to 90% liquified, the majority of the organic matter has been spent.” This leaves indigestible or slowly-digestible materials in the pit, including oils, fatty acids, lipids and soaps that tend to float on top of the liquid in

the pit.

All this creates an environment where a specific group of microbes can flourish, namely methanogens that produce methane. “The bubbles in manure foam can encapsulate up to 70% methane,” Chodur said.

When the foam in the manure pit is disturbed through regular management activities such as manure agitation and/or pumping and power washing, large amounts of methane may be released into the air space above the slats. This methane can ignite easily and may lead to deadly barn explosions and flash fires.

- Odor. Odors are simply nutrients that are leaving the pit or lagoon. They volatize into the atmosphere. Examples are ammonia smell or irritant is nitrogen. Microbes produce gazes when they digest and tie-up nutrients. Some gases may be hazardous. Pits and lagoons on the farm can create a major odor nuisance when the manure digestion process is out of balance.

What’s going on?

All these challenges go back to feed ingredients and environment. While any manure pit or lagoon is filled with microorganisms, the native population of microbes often can’t produce sufficient enzymes to digest the volume of manure and break-down toxins fast enough. When there aren’t enough beneficial microbes to handle the amount of manure present, a host of undesirable consequences can result.

Bring in the right biology

When manure is treated with an effective microbial product, however, the added microbes help break down and remove a greater range of organic matter at a faster rate. The right bacterial cultures kick the digestive process into high gear. These aggressive digestive microbes lift the sludge zone on the bottom of a manure lagoon to the top aerobic zone, where the manure is rapidly digested and liquefied.

During this process, the pit or lagoon is agitated, creating manure consistency from top to bottom. This also leads to improved agronomic value of the manure, since nutrients aren’t left behind in sludge on the bottom of the pit or lagoon.

Harnessing the power of microbes helps improve the value of manure while reducing handling costs. This can make a big difference in your bottom line and provide a wealth of benefits throughout your farming operation.

ProfitProAG, which has been in the manure treatment business for more than 20 years, offers a variety of options and products, including Manure Master PlusTM, a biological manure additive made up of a diverse array of microorganisms to help improve manure storage and application. Manure Master PlusTM keeps crusting down, helps cut down on solids, reduces odor & foaming, improves potassium and phosphorus availability, and makes manure more usable.

It works, because it’s based on the sciences of biology and chemistry and the right consortium of microbes. Manure pits with an alkaline pH level are the most prone to fly problems, for example, since insects’ digestive tracts are primarily alkaline. “If you can maintain a slightly acidic pH, it will help you manage a lot of fly problems,” Chodur said.

This requires an acidic pH range of 5.8 to 6.2. Pits that spawn fly problems, however, tend to have an alkaline pH range of 7.5 to 8. For new ProfitProAG clients facing this situation, Chodur mixes a solution of Manure Master PlusTM microbes in a low pH (2.8 to 3.1) formulation. “We’ll push 300 gallons through a 2-inch hose and hit all the pump outs to break up the crust. You’ll see thousands of maggots crawling out of the pump-outs within seconds, because it’s that acidic to their bodies.”

While this mixture kills most of the maggots, the solution is safe for people and animals, since it uses organic acidifiers, Chodur added. “It’s great to tell customers, ‘I killed a few thousand potential flies for you today.’”

Practical solutions offer proven results

ProfitProAG recommends using 40 gallons of Manure Master PlusTM per 1 million gallons of manure annually. When starting treatment, use 15 gallons per 1 million gallons of manure. This first treatment should occur two to three weeks after spring or fall pump-out, when the pit/lagoon is at its lowest capacity and fresh manure has accumulated. Following that, use 2.5 gallons of Manure Master PlusTM per 1 million gallons of manure each month for 10 months. However, ProfitProAG can help you develop an effective manure treatment plan beginning at any point during the year.

Since Richard Rosener started using Manure Master PlusTM, he hasn’t had a buildup of solids in his pits. “When you pump out the manure, it pumps right down to the concrete,” said Rosener, who farms near Vail, Iowa. “It’s a lot different than those farmers who say their pit only holds half of what it used to, because of all the solids building up.”

Odor has been a non-issue, as well. “After using Manure Master PlusTM in my pit, there was no odor present when I emptied it last spring and this fall,” Rosener said.

What pleases him most? When people visit the Rosener farm and say, “I can’t believe you have a hog farm here.”

ProfitProAG can formulate the right Manure Master PlusTM mix for your needs. Totes of the pre-mixed product can be shipped to your farm so you can add the product to the pits yourself. You can also let the ProfitProAG team handle monthly manure treatments for you.

Steve Jaster appreciates the convenience of ProfitProAG’s service, while his manure pumping crew likes the results. “They comment on how easy it is to agitate the manure,” said Jaster, who farms near Medford, Minnesota. “There aren’t solids floating on the top anymore, and there’s no pile of solids that can’t be pumped out of the pits. The more liquid manure you can pump, the better.”

While Manure Master PlusTM takes a modest investment of money and time to work, the long-term results are worth it, Jaster said. “Some farmers are always looking for the cheapest product or a silver bullet to control flies. My advice is to get Manure Master PlusTM and stick with it. When you manage flies from the start, you have one less thing to worry about.”

Biologically treating manure takes know-how and the right products to keep the microbes in balance, Chodur said. “If you have issues with crusting, flies, foam, bottom solids or odor, it indicates your biological manure digestion system is out of balance. You just need to learn more about how to manage manure properly, and we’re here to help.” With ProfitProAg’s experience and dedication in the manure treatment business and products, you will learn more about how to manage manure properly. We are here to help!

If your manure pit is foaming manure pit, you need answers—now. Just ask John Yoder, vice president of manure-handling equipment for Eldon C. Stutsman, Inc., eastern Iowa’s largest retail and wholesale supplier of agricultural products. Plenty of products claim to manage foam, but not all deliver on their promises. A few years ago when the Stutsman team heard about ProfitProAG’s Manure Master FoamAway, they were interested but skeptical. Around this same time, a farmer with a foaming pit was calling the Stutsman team for help, and time was of the essence.